Investment Casting Automotive Industry.

Lestercast are leading providers of quality precision Investment Castings to the automotive industry. Over the last 50 years, we have been delivering cost effective solutions to most major OEMs – Jaguar LandRover, Volkswagon, Bentley, Porshe just to name a few. In this time we have manufactured parts for thousands of suppliers and continue to be the number one choice for quality investment castings.

Lestercast are accredited with the automotive specification and quality management specification IATF 16949:2016 and we’re also proud members of the Cast Metals Federation. Lestercast have been ISO:9001 certified for over 40 years and have a reputable service for quality within the automotive industry. Lestercast are proud members of the Motorsport Industry Association (MIA) and have been sponsoring the MIA Business Awards for over 9 years. Please visit our quality page for more information.

We always aim to provide the highest quality customer service alongside our products and are proud to be achieving an overall five star rating from our automotive customers.

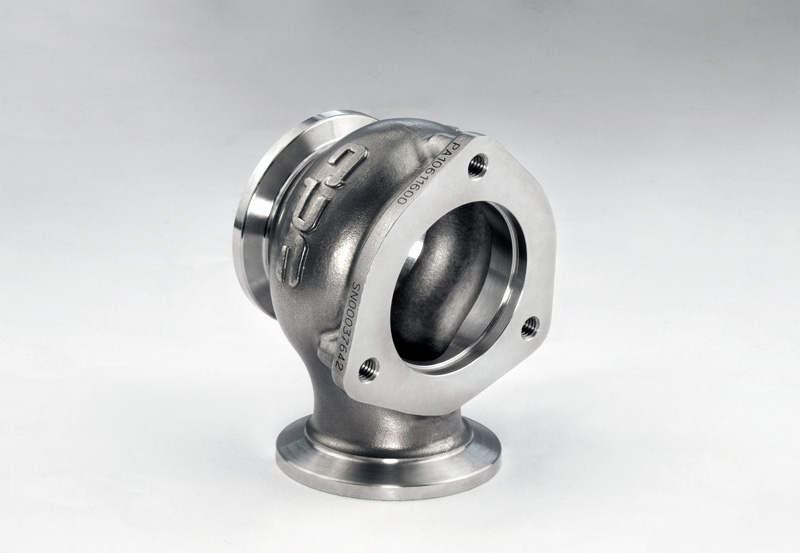

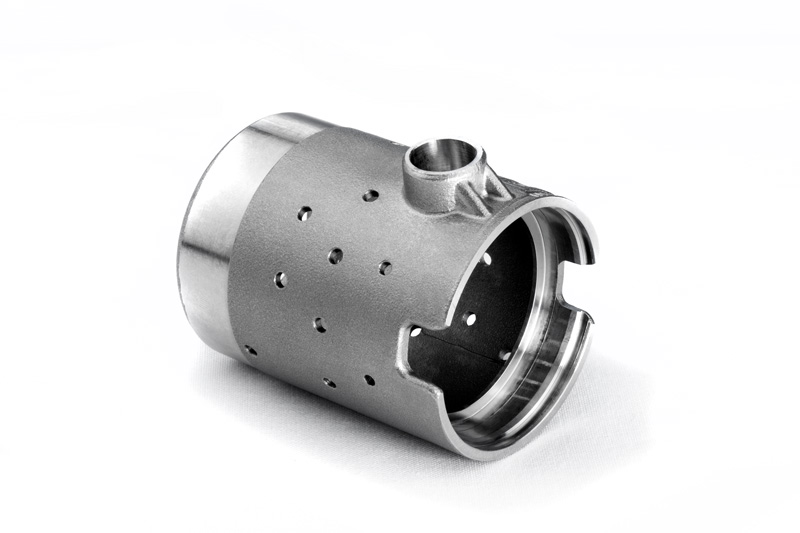

We produce thousands of components for the automotive industry using investment casting techniques. The complex, near-net shape & thin walled parts we are able to achieve through investment casting, provides a popular cost-effective alternative to other casting methods. The Investment casting process allows a wide range of metals to be cast such as ferrous, non-ferrous metals, and high temperature alloys, making it an ideal choice for automotive and motorsport industries. With investment casting there is little wastage, rapid prototyping options to eliminate expensive re-tooling costs and little or no machining required.

We supply investment castings to a wide range of companies across the automotive sector. Investment casting produces highly complex quality parts making it a popular choice for heavy goods & construction vehicles, tractors and agricultural machinery. Components such as transmission parts, engine parts, brakes, brackets, housings, rods, gears, door handles etc are very popular choices.

We pride ourselves on our modern foundry and up to date technology which we believe keeps us ahead of the rest. Our facilities include meeting & conference rooms allowing us to offer on-site consultations and spend time with our customers to discuss the latest projects and developments. We offer new customers the chance to have a tour of our modern foundry and facilities, and meet the staff which the delivery of our quality components possible.

Each new product has a CDP – Component Development Plan as standard. This provides our customers with regular updates of your products progress. We feel this allows our projects to run in the most economical way and benefits our customers considerably.

Experts in Aluminium Investment Casting

With the development of energy efficient automotive vehicles, the requirements of components and alloys are changing significantly. We are now producing a great number of parts for the electric automotive market. Aluminium investment casting is in high demand, allowing automotive manufacturers to produce lightweight parts which will not compromise the vehicles performance. Lestercast invests in the latest technology and develops the most advanced techniques enabling us to manufacture high quality components each and every material Lestercast offer.

If you would like to learn how investment casting could work for your company, please give us a call or contact us using the online form.

Benefits of Investment Casting in the Automotive Industry

THIN WALLED PARTS

HEAT RESISTANT PARTS

NEAR NET COMPLEX PARTS

NO MACHINING REQUIRED

NO QUALITY REDUCTION FROM PART TO PART

HIGH TEMPERATURE RESISTANT ALLOYS

Common Parts that are Manufactured for Automotive Industry

Exhaust Stubs

Badges

Aluminium battery plates

Transmission Components

Door Handles

Housings

Wing Vents

Cover Plates

Engine Parts

Brake Parts

Wastegates

Flywheels

Manifolds

Power Steering

Interior Components

Watch The Manufacturing of ‘The Flying B’ at Lestercast for the First Time!…

Bentley Motors’ Case Study – ‘The Flying B’….

Lestercast have proudly been manufacturing the iconic ‘Flying B’ on behalf of Bentley Motors, using investment casting techniques, for over 14 years.

The upright bonnet mascot is now on it’s sixth iteration, with the latest being the most complex, having crystal wings which illuminate as part of the lighting welcome sequence.

This Case Study, written by Bentley Motors gives an insight into the investment casting process and the manufacture of the ‘Flying B’.

When Bentley Motors asked to film the manufacturing of the ‘Flying B’ at Lestercast, we were only too pleased to oblige….

Metals Commonly used within the Automotive Industry

Aluminium – highly popular for electric & performance vehicles

Inconel– High temperature resistant alloy used in Motorsport

Hastelloy– High temperature resistant alloy used in Motorsport

Stainless Steel – 316 – Badges, vents, handles and interior components

Please click on the links above to visit our specific alloy pages.