“Thank you for making me happy!”

As a trusted investment casting UK partner, Lestercast supplies major OEMs and multi-tier suppliers across global industries with precision cast components. With over five decades of experience, we deliver high-quality investment castings in a broad selection of metals and specialist alloys.

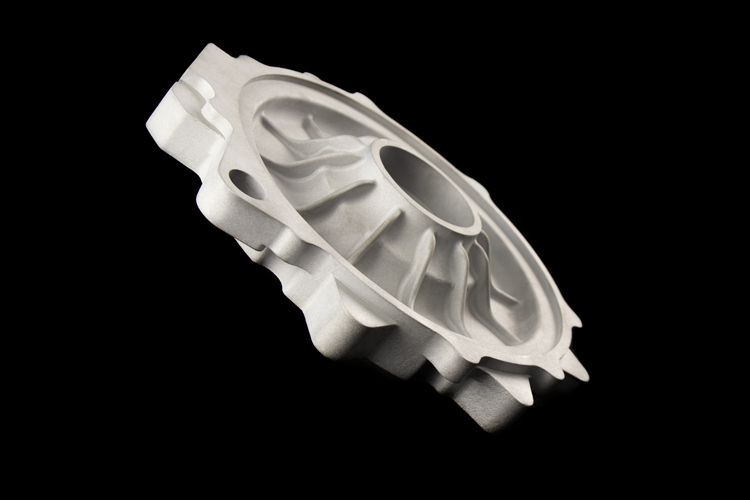

Investment Casting

We manufacture high quality bespoke precision castings in Steel, Stainless Steel, Aluminium, Nickel & Cobalt Superalloys, Brass & Bronze & Zinc.

By providing innovative solutions, quality products and excellent service, we deliver a ‘complete investment casting package’. Lestercast pride ourselves with an excellent on-time delivery performance and also offer on-site stock holding facilities. We are able to offer our customers high quality lost wax castings manufactured in our UK foundry in Leicestershire, as well as from our partner facility overseas. If you would like to learn about the investment casting process click here.

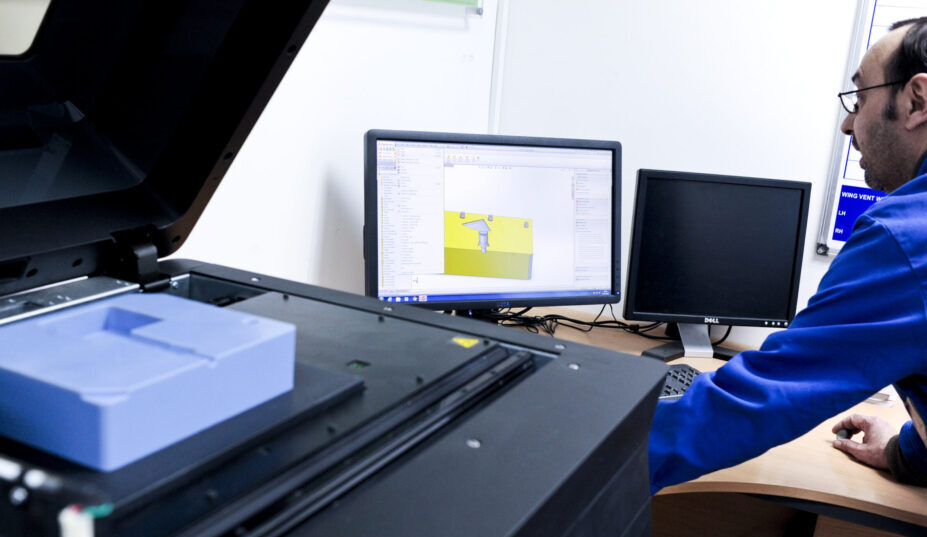

Rapid Prototyping

Lestercast have the latest and best 3d printing technology available on the market today. Wax patterns can now be printed quickly, in-house, with a far superior finish to previous 3d printed waxes. This means that we can now supply castings from the rapid prototyping route that have a comparable surface finish to castings made from hard tooling method, in a fraction of the time.

With our rapid prototyping facilities, prototype castings can be tested and verified prior to commencing with production tooling.

Investment casting vs 3D metal printing? – A comparison table can be found on our rapid prototyping page.

Why Choose Lestercast Investment Casting Services?

- Vast range of metals and nickel based alloys

- Optional on-site rapid prototyping facilities

- Competitive prices with UK & overseas foundry

- Free secure on-site UK stock holding facilities

- Experienced project support engineers

- Latest technology

- Component Development Plan for each new component

- 95% on-time delivery

- Tours for new customers

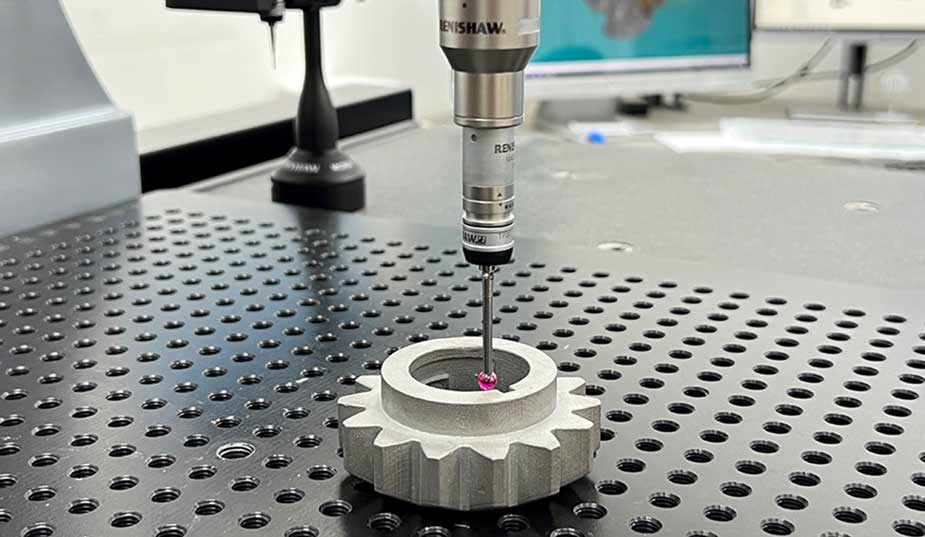

- On-site inspection facilities

- Wide range of treatments and finishes

- Superior quality with;

- ISO 9001:2015

- IATF 16949

- JOSCAR registered

- Fit4Nuclear

- Cyber Essentials

- Member of

- Cast Metals Federation

- Make UK

- Nuclear Industry Association

- Motorsport Industry Association

Investment Casting FAQ’s

What is investment casting?

Investment casting is a precision casting process used to manufacture metal parts by creating a wax pattern, coating it in ceramic, and then pouring molten metal into the mould once the wax has been removed. Investment casting is widely used when precision, repeatability, and material performance are critical.

Can you cast jewellery?

Investment casting is an ideal casting technique for jewellery manufacture as the process produces precise, intricate parts with a superior surface finish. Lestercast manufacture engineered parts for companies across many industries, but we do not cast jewellery items or precious metals.

How much does investment casting cost?

Investment casting is a more cost-effective than die casting for smaller to medium volumes. It can also be more cost-effective than 3D metal printing. Casting costs depend on volumes, size and complexity of components.

When should you use investment casting?

Investment casting can be a good alternative to machining, die casting, sand casting or 3D metal printing. Near-net-shape components with an excellent surface finish, can be produced without the need for excessive machining.

What materials can be investment cast?

Lestercast can investment cast components in carbon steel, stainless steel, aluminium, brass, bronze, and high-temperature nickel-based alloys. Please visit our technical page for more information.

Do you support prototyping?

At Lestercast we have our own in-house rapid prototyping facilities. This allows us to 3D print wax patterns and manufacture precision castings much faster than conventional techniques. Please visit our rapid prototyping page for more information.

Can you handle small batch production?

Investment casting is ideal for small-volume production. In combination with our rapid prototyping facility, allowing customers more design freedom for ongoing component development.

What are typical UK lead times?

Investment casting can typically take anywhere between 7 days and 2 weeks. Lestercast only produce investment castings, so with 50 years expertise, our advanced processes, techniques and rapid prototyping facilities allow us to achieve the fastest times possible. Our current record stands at 5 working days for an investment casting.

What tolerances can be achieved with investment casting?

On a casting of 50mm³ Lestercast can achieve a tolerance of ± 0.4mm. A guide to our tolerances can be found here.

We Have The Latest Technology….

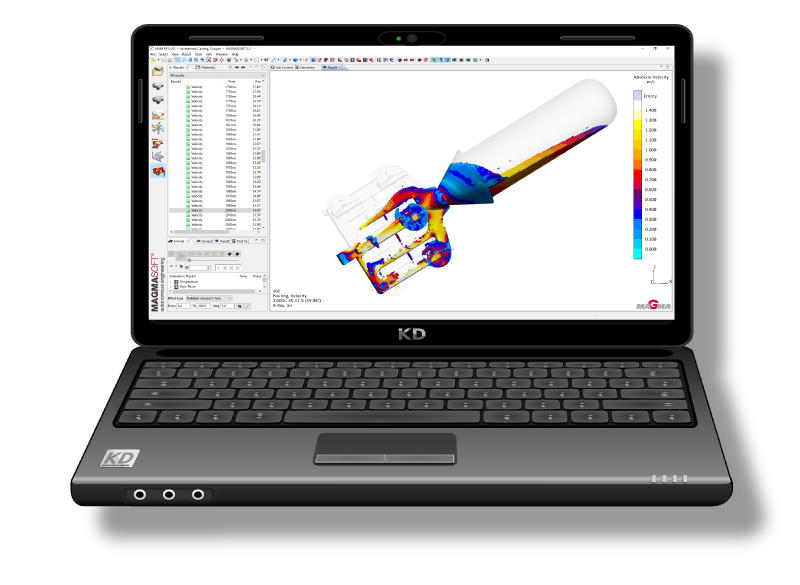

MAGMASOFT® Simulation Software

We have the latest technology on hand, including simulation software, to make sure that your investment casting project runs as smoothly as possible from design through to delivery.

The Investment Casting process has benefited many industries as an economical route to cast near-net-shape metal parts with high geometric complexity and dimensional accuracy. Lestercast use MAGMASOFT® investment casting simulation software as a virtual prototyping tool for eliminating physical casting trials. This improves investment casting quality which significantly reduces production costs and time.

Magmasoft is a brilliant scrap prediction and prevention tool. It shows the user how and why a casting method may or may not work by providing a variety of result types. Collating this information and applying our extensive knowledge and experience ensures that the best possible design is being used, before any tools have been cut or any waxes have been produced.

Some benefits of investment casting simulation:

- Detecting areas of concern with a casting design.

- Reduction of scrap

- Continuous improvement of casting quality

- Shorter production times

- Predicts filling and solidification behaviour during the casting process.

Reverse Engineering:

At Lestercast, our in-house 3D scanner allows us to scan parts which have no CAD available. We are able to import the 3D scanned CAD model into MAGMASOFT® simulation software, enabling us to produce the highest quality precision castings in the most cost effective way.

Did you know….Investment Casting is also known as Lost Wax Casting & Precision Casting?

If you would like to learn more about the lost wax casting process please visit our investment casting process page. You can also go to our about us page and watch our corporate video, where you are introduced to some of the team, learn about our investment casting services and watch the casting process at our facilities in Leicestershire.

We produce over 1 million parts annually for 170 different global companies, using over 100 metal specifications, across 20 different industry sectors.

Looking for a New Supplier?

We are so proud of our modern facilities that we regularly give tours to prospective customers. If you would like to see what we can offer your company, please get in touch!

Photos of our casting facilities can be found in our Gallery on the UK Foundry & Facilities page, photos of the casting process can be found on our Investment Casting Process page.

Our Customers across the Globe…

Component Development Plan (CDP)

Every new project includes a Component Development Plan (CDP) as standard.

You receive:

-

Itemised schedules

-

Manufacturing timelines

-

Progress updates

-

Photographs

-

Documentation

-

Key milestone reporting

Whether produced in the UK or overseas, you always have full visibility of your project.

What Our Customers Say About Us……

“Five star communication, Five star delivery, Five star service, Five star order”.

C. Bennett.

“Our design request was dealt with swiftly and with no hassle. Great supplier.”

C. Ward

“We are kept informed with regard to progress of our orders and that solubles are kept in stock, this helps lower lead times.”

C. Slenzak

“We’re really happy with the service by Lestercast. The team were really responsive and friendly, indulging our curiosity about the process with patience. It was great to see our design turn into the beautiful solid bronze end result, a really quality item produced by very skilled and knowledgeable people.”

A. Johnen

“Excellent quality product supplied on time”

(Anon) Procurement Manager

“Great service, quality products.”

N. Wright

“A nice company to do business with.”

P. Buschgens

“Lestercast has always been very attentive to any request sent.”

(Anon) Senior Buyer

“Lestercast continues to be one of our most suppliers.”

Senior Buyer

“Lestercast are so easy to deal with, we have a great relationship, the communication channels are excellent. There is always somebody there to deal with our enquiries with a quick and efficient answer. Lestercast offer a stockholding facility which is a massive help to have the stock available at a moment notice, this enables us to hold minimum stock levels. Overall, a pleasure to work with.”

(Anon) Procurement Manager

“As a long-standing customer of Lestercast, I always receive a first-class service from a responsive and highly experienced team”.

(Anon) Engineering Manager

Memberships & Accreditations