Inspection is key in product manufacturing which is why Lestercast have developed a digital in-house system through the use of various robotic machines to enhance verification and reduce lead time.

In any work environment, finitely assessing each and every individual manufactured product is equally as important as the manufacturing processes themselves and is always done by hand by our qualified inspectors. Prior to shipping to the customer, dimensions must be accurately measured to ensure every single measurement conforms otherwise the parts are rejected.

Modern advancements in technology are a prerequisite for any firm and most certainly in a manufacturing firm where competition is at an all-time high.

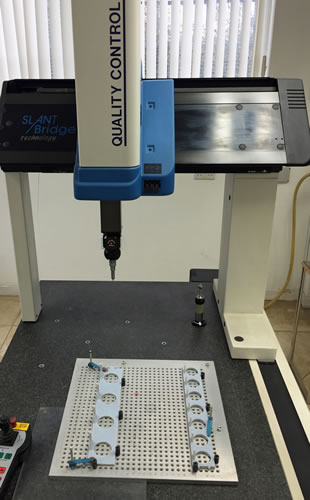

Here at Lestercast we have a CNC CMM (Computer Numerical Control – Coordinate Measurement Machine) which does what the name suggests. Linked up with a specialised computer programme, the machine robotically assesses dimensions for critical data analysis and improves process capability.

Bespoke jigs are specifically manufactured by our 3D printer to fit together with the cast and machined part to hold it in place. This is then linked up with the computer programme and robotically checked for accuracy thus robotically enhancing our in-house inspection procedures.

“A job which would ordinarily take perhaps a day and a half, through this new system using both the CMM and 3D printer on site, now takes half a day which is a huge advancement for our continuous improvement.”

Quality Manager – Pete Johnson

* Please note – for data protection reasons, the cast part cannot be shown within the bespoke jigs in the photographs.

Should you wish for a tour of our inspection and foundry facilities please contact us and we’d be delighted to show you around.