Lestercast are proud to appear in this months Foundry Trade Journal International. An article has been published covering the ICME Northern Branch Technical Seminar, in which Lestercast’s Technical Manager, Russell Gray gave a presentation on the ’Manufacture of the Flying B’…..

Lestercast appear in the Foundry Trade Journal International

ICME NORTHERN BRANCH – TECHNICAL SEMINAR 2025

The ICME Northern branch held its annual technical day at the AMRC Knowledge Transfer Centre at the Advanced Manufacturing Park in Sheffield (UK) on Thursday 15th May, with a packed audience enjoying the newly refurbished conference suite.

Opening proceedings for the day, national senior vice president Simon Alexander FICME welcomed all the delegates and thanked the guest speakers, organisers and event sponsor Omega Sinto Foundry Machinery Ltd for their support. Noting the attendance of several non ICME members, he highlighted the “value proposition” that ICME represents in terms of strength of membership. “I trust the level of technical expertise here today is a reminder of the value of ICME as an organisation, showing the skills, knowledge and networking opportunities the institute offers, along with a range of other benefits of membership such as training provision including bespoke needs,” he said. Along with the teams at ICME and CMF, at Northern branch level Steve Illingworth Prof MICME was singled out for “working tirelessly” for several weeks in organising the event.

Kicking off the technical presentations, Sam Garner MICME of Omega Sinto Foundry Machinery Ltd presented a case study, ‘Enhancing production efficiency: Fonderia Steel Foundry’s advanced no-bake moulding system.’ The project has seen Omega Sinto work with the Italian foundry to enable them to increase both productivity and quality thanks to the installation of the new moulding system, incorporating mechanical and secondary thermal reclamation, an autoblend temperature adjusting system, a fast loop, modular design method with automated pattern change, rollover and automatic mould strickle. The mixer is paired with the Omega Sinto IRIS (RFID tagging) technology. The system also includes a purpose built facility housing a 200-capacity vertical mould stacking system.

In short, he explained how the foundry is experiencing less waste of sand and chemicals thanks to this fully controlled no-bake moulding system, with a return on investment of less than two years. Scrap rate is also reported to be down by eighty per cent, sand reclamation up 95 per cent and disposal costs reduced by seventy per cent. Garner highlighted how this equates to 110 tonnes of CO2 emissions saved. The mechanised fast loop is credited for a significant increase in productivity levels.

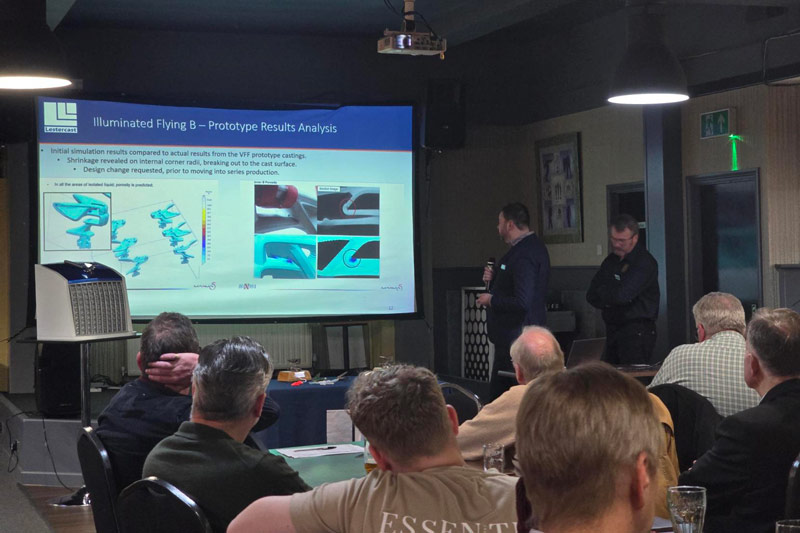

Maintaining the case study theme, Russell Gray EngTech Prof MICME of Lestercast Ltd provided a fascinating insight into the redesign of the Flying B mascot which is included, as an added extra, on certain Bentley car models, in his presentation ‘Bentley B: the story of a British manufacturing icon.’

Lestercast has the “honour” of being the only company in the world to make the Flying B, which is produced by the lost wax (investment) casting process. Detailing multiple iterations from the original in 2008 to the latest design, Gray showed what can be achieved with design and technical expertise.

With thick and thin walled sections, isolated sections, complex geometry, very tight radii in corners and casting tolerances that are extremely tight, Gray noted that the “design is appearance driven rather than designed for manufacture,” something that resonates with many foundry personnel. Lestercast is currently making 85 a week for Bentley Motors.

In his presentation ‘The hybrid and digital core shop of the future,’ Rudi Wintgens Dipl Ing of Laempe Mossner Sinto GmbH, spoke of the great strides made to improve the core shop using digital and automated technology (refer to the April/May 2025 issue of Foundry Trade Journal for a detailed insight into this). He told delegates: “We think it could be an option to transfer gigacasting into 3D sand printing.” He also mutted the idea of a possible core hub – with one central supplier, where the foundry buys in cores to concentrate on its prime focus. “Foundry is a six-thousand-year technology, but every day is new for us,” he enthused. “Let’s try to be the trend setter for our customers and their customers.”

In an amusing presentation, Simon Olive FICME of Maxima Engineering Ltd questioned the metallurgy of cast iron. Relying on input from metallurgists in the room, including Prof John Campbell FICME, he asked: ‘Is the metallurgy of cast iron a riddle – wrapped in a mystery – inside an enigma to you?’ Using video footage from his own kitchen, he showed how “bizarre” metallurgical reactions can be.

Richard Heath Prof MICME, of the Cast Metals Federation, offered a stark warning to attendees concerning the “poor performance” of UK foundries, following visits from the Health and Safety Executive (HSE) as part of their silica campaign (read more about the outcome on page 88 of this issue). He spoke of the financial impact this looks set to have on the cast metals sector, and of how foundry leaders needed to “step up”. He said: “There is an inherent underpinning of knowledge needed in the foundry industry. Why haven’t we achieved this in the 25 years we have been reporting on it? We’ve created a ‘target rich’ environment according to the HSE.”

“There is a growing market for inorganic binders,” said Dr Christian Lustig of Huttenes-Albertus in his presentation, ‘Meeting the challenges of the future with inorganic binders’. “In 2005 they accounted for less than two thousand tonnes, but by 2022 this had risen to almost twenty thousand. China in particular is a big market.” He notes that the switch from the internal combustion engine to EVs still provided a market for inorganic binders for various parts, including subframes.

He considered the “new challenge” of aluminium to iron casting – the brake disc concept. “We need more water based coatings with parts needing to be coated immediately after production, this project is now ready to transfer to serial production” he said. “Now we are looking at other components with test cores taking place at our Centre of Competence in Hannover, and we are thinking of hybrid technology with a combination of organic and inorganic cores.”

He noted how constant R&D is required because: “The previously unthinkable is now feasible with structural castings to be manufactured by high pressure diecasting. The challenge is to use only sustainable technology.”

Steve Packenham Walsh of SecalTKS Ltd unveiled what he said would “revolutionise” the industry in his presentation, ‘Award winning energy efficient gas burners.’ He showed the new gas burner system that he claimed reduces process time by two thirds, consumes less gas than current radiant burners, reduces CO2 emissions, and eliminates thermal shock.

Again, with the use of case studies in Ryobi and Weir Foundries, he made a case for the new technology, which he said would also impact the refractories world thanks to an ability to protect refractory material, thus extending its lifespan.

Matthew Cawood of AMRC gave an overview of the company, which has a key focus on: sustainability, industrial digitalisation, future products and processes, and supply chains. He said: “We are purely pre-production. The castings group is make up of 22 per cent Catapult funding, fifteen per cent grant funding and 62 per cent commercial activities – mostly because the companies we work with want to own the IP.”

He highlighted several projects, including one to investigate the use of hydrogen as an alternative to other fuels and he put out a call to action for companies to contact him at AMRC about collaborative research (m.cawood@amrc.co.uk)

Will Jeffs of CTi, closed the event making clear that the organisation is “not a competing steel foundry, as the vast majority of cast work is titanium, predominantly for the defence sector.”

He explained about the organisation’s future expansion plans, which will include a move away from the AMRC site and back into a more central Sheffield location over the next twelve months. This is largely due to a need to expand facilities, which is not possible in the current location. He said additional staff will be recruited and trained and key equipment will be installed in 2026, with both sites operating in tandem during the expansion period.

Delegates were then invited to tour the Cti/Nuclear Manufacturing Group facilities before departing.

The ICME Northen branch thanks all those taking part in the event and Omega Sinto Foundry Machinery Ltd for sponsoring the day.

Thank you to Lynn Postle, Editor of the Foundry Trade Journal, for supplying the article.