What is Investment Casting?

The Investment casting process involves producing wax patterns (through tooling or 3d printing), and coating the wax patterns in several layers of ceramic slurry to create a mould. The mould is then transferred to a boiler clave before firing the mould to melt and remove the wax pattern. Molten metal is then poured into the hollow ceramic mould to produce a cast replica in a range of metals. The individual wax patterns can only be used once because the wax is melted out as part of the Investment process. However, each wax pattern is created by manufacturing a die or tool which can be used repeatedly to recreate the same wax pattern and metal final part.

Investment casting, as a process, is one of extreme intricacy because the final metal casting can create thinner sections than other casting methods. Inevitably investment casting has a better tolerance and finish, and therefore it is ideal for casting complex, intricate and fine metal components in a variety of fields and sectors. The ability to recycle the wax and the metal (from cut off and the runner system) is also advantageous in respect to cost and environment.

Investment casting is a process that has been in existence for hundreds of years, and although the methods have altered slightly using new techniques and technology to improve quality and precision, the principles have remained the same.

The Benefits of Using 3D Printing With Investment Casting

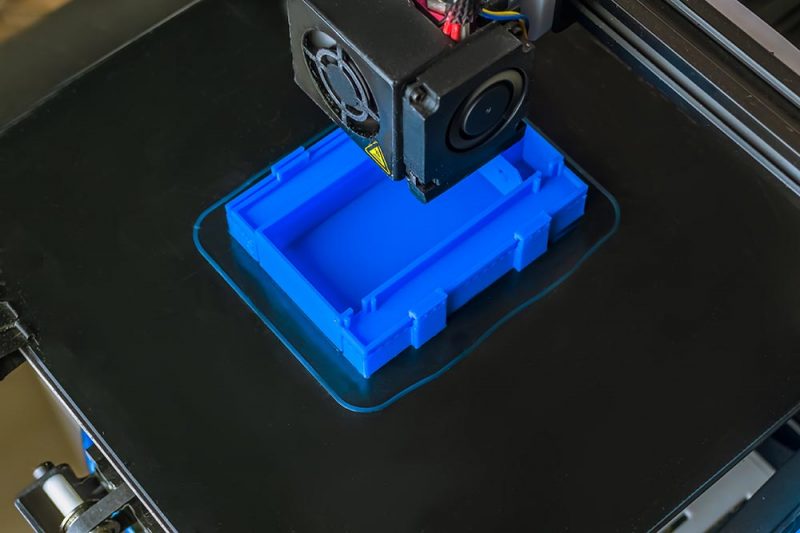

3D printing, Rapid Prototyping and Additive Manufacturing are all terms used to describe the same process, all of which involve the creation of complex structures and components in formation by the layering of materials.

Additive manufacturing provides several advantages for the Investment Casting process, the most obvious being that it eliminates the need for tooling altogether. This is ideal for prototyping during the testing stages or if the customer wishes to produce smaller volumes. Many customers choose 3d printing rather than tooling in the early stages of production and swap to tooling at a later date. This allows the customer to keep the initial costs down on an early production part. The other advantage of 3d printing wax patterns is that it reduces lead times considerably. Wax patterns have a fast production time compared to hard tooling times which can take weeks.

By using the rapid prototyping method and 3d printing the wax patterns for investment casting, the customer is able to produce complex designs which may not be possible with tooling.

The 3D printed wax patterns are used in exactly the same way as the traditional wax patterns and 100% recyclable too.

For more information on the advantages of using our 3d wax printing services, please visit our website. Here you can also find more detailed information on the Investment Casting process, the types of metal we cast and the benefits of this process.