FAQ’s regarding….

3D Printing Wax Patterns vs Traditional Wax Patterns;

1.) How does the cost of a 3d printed wax pattern typically compare with a traditional wax pattern?

If comparing an individual, traditionally produced wax pattern and a 3d printed wax pattern, the price of the 3d printed wax would be significantly higher.

The majority of the cost associated with traditional methods are from the manufacture & material of the hard tooling which is required to produce the wax pattern. Tooling can cost from £2000 upwards, with the price increasing significantly, depending on the complexity and size of the pattern. Although one tool can produce as many as 20,000 – 40,000 patterns (again, depending on size and complexity) in it’s lifetime, before quality reduction is evident.

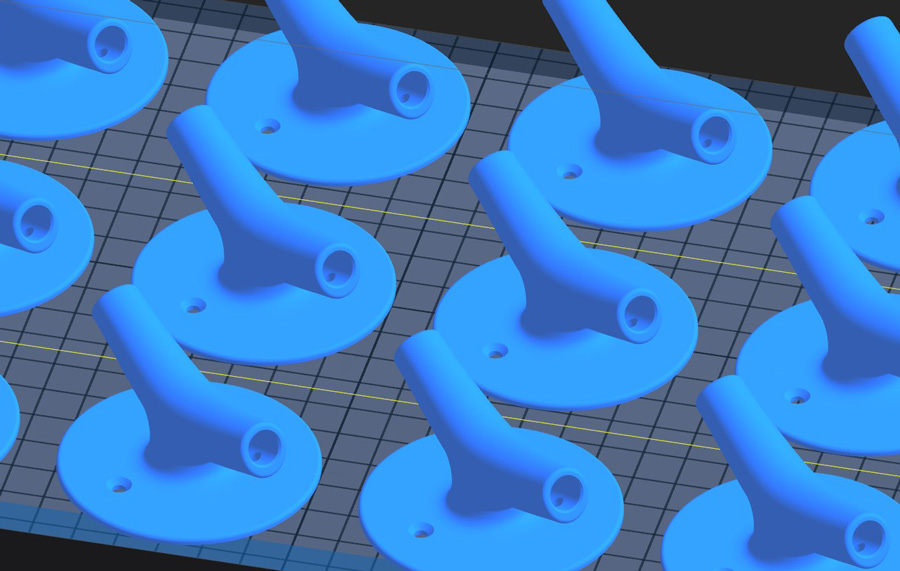

3D printed wax patterns can be produced in hours from CAD and simply modified as and when required. Greater complexity can be achieved by 3D printing the waxes, due to the lack of design restraints on draft angles.

2.) At what part quantity does it usually become economical to switch to traditional investment casting?

Every part is individual, and it depends on the dimensions, complexity and material of your component.

Our engineers work with each customer to discuss the most cost-effective method for your particular project. Many customers use printed waxes initially, swapping to hard tooling when production levels increase.

3.) How does the surface finish and tolerances compare between traditional investment casting with rapid investment casting?

Prototype wax can deliver a very similar surface finish to production wax from tooling, which would be around 3.2ra. Our new next-generation 3D Printer is producing wax patterns that are vastly better than previous machines, with build lines only visible on certain surfaces. We are now producing castings with a comparable surface finish to castings produced from traditional waxes. Please see our investment casting process page for more information.

4.) Is the rapid prototyping method more prone to defects?

No. The castings are cast in the same way as traditional methods.

5.) Can rapid prototypes parts have equally thin sections as traditional wax patterns?

Yes. Thin-walled sections are possible in printed waxes, with a minimum wall thickness of 2mm depending on complexity & dimensions of part.

6.) How does investment casting (using the rapid prototyping route) compare to 3d metal printing?

We have put together a quick comparison table to clearly identify the advantages and disadvantages of 3d metal printing when compared to rapid prototyping with investment casting. The main disadvantages of 3d metal printing are higher costs, longer lead times for large parts and the limited choice of metals available.

If you would like a tour around our facility, to see for yourself the quality of the castings which can be achieved through rapid prototyping, please get in touch.